Ty45

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Ty45-145, Warszawa Praga

depot, July 1961. Photo from my collection. Ty45-139 + 30D43-68 (HCP

1047/1947), Kościerzyna depot,, Another picture of the Ty45-139, taken on September 23, 2013. Ty45-149 + 30D43-318 (HCP

1058/1947), plinthed in Kluczbork;

photo taken on Ty45-205 + 32D47-221 (HCP

1126/1947) in pristine condition, plinthed in Iłowo; photo taken

on The same locomotive, photographed on July 1, 2015, in need for a

refurbishment. This Ty45-94 + 27D47-3 (Fablok 1638/1947) is plinthed at

the Ostrów Wielkopolski depot; photo taken on Ty45-94 was externally refurbished in late 2005 and now looks much

better; photo taken on Ty45-379 + 27D47-35 (HCP

1388/1949), Wolsztyn depot, Ty45-217 + 30D43-217 (Fablok 1752/1947),

withdrawn in 1984, is plinthed at the Tarnowskie Góry depot; Ty45-39 + 32D43-22 (HCP

988/1946), preserved at the Zduńska Wola Karsznice depot; photo

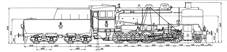

taken on The same engine, photographed on August 13, 2008. Side drawing of Ty45 + 32D47; source – PPN. Ty45-20 (Fablok 1598/1946) at the Industry

and Railway museum In Jaworzyna Śląska,

The same engine, photographed on July 8,

2009. Ty45-2560 (Fablok 2560/1950) was used by

the Kotlarnia

sand mine and has been plinthed at the company’s

premises; photo taken on Another picture of the Ty45-2560, taken on Ty45-6 (Fablok

1584/1946), abandoned near the Kędzierzyn-Koźle

depot… …and another picture of the same engine; both

taken on April 18, 2009. Ty45-158 (HCP 1068/1947), owned by TOZKiOS railway fan society; Pyskowice, May 2, 2009. Another Ty45 from the TOZKiOS

collection: Ty45-125 (Fablok 2592/1951),

photographed on the same occasion. An unknown Ty45, location and date unknown.

Photo by A.Żmuda (postcard from my collection). Several more photos from my collection.

Ty45-158, abandoned in Krzeszowice (date unknown)… …Ty45-390 in Międzyrzecz,

date also unknown (photo by Martin Stertz)… …and another photo by the same author:

Ty45-292 (HCP 1144/1948), Pyskowice depot, June 11,1979. One more picture of the Ty45-20: Jaworzyna Śląska, May 25, 2016. Ty45-379 photographed during its visit to

Warsaw on June 17, 1995. Photo by Marek Niemiec

(from my collection). Ty45-386 (Fablok 2546/1950), photographed

at the Chabówka railway heritage park on May 6,

2017. Ty45-360 (HCP

1356/1949) with a local passenger train, photographed near Zabrze on June 10,

1979. Photo by Martin Stertz (from my collection). |

Since

the introduction of Ty23 in mid-1920s until the end of the steam era, Decapods dominated heavy freight

traffic in Drawing

on experience with ex-German locomotives, it was decided to fit a fully

enclosed driver’s cab, which changed the silhouette. Steel firebox replaced

copper one, previously used, and exhaust-steam injector was fitted. Contrary

to Ty37, circulation tubes were initially deleted, but they were fitted in

last production examples and later standardized. Grate and ashpan were later modified during overhauls and some

engines were fitted with coal feeders and/or rocking grates. From 1964

onwards, several Ty45s (probably seventeen) were converted to oil firing, but

this was soon abandoned and they were finally restored to initial

configuration. Ty45s were typically coupled with 32D47 tub tenders which,

compared to 22D23s used with Ty37s, took much more water (32 cu.m instead of 22 cu.m); coal

capacity was also increased from 10 to 12 tonnes.

New tenders were manufactured by Pafawag company of Production

of Ty45 started in 1947, both at Fablok in Chrzanów and at HCP (Cegielski) in Ty45s

remained in service throughout the country until the end of steam era,

together with other Polish Decapods.

With mounting supplies of heavy diesel locomotives since mid-1960s and

progressing electrification of main lines, most of them were withdrawn from

line service in the 1970s and relegated to switching, mainly in In

1999, seventeen Ty45 still existed and two (Ty45-20, Fablok 1598/1946, and Ty45-379,

HCP 1388/1949) were operational.

According to www.holdys.pl/tomi,

fourteen have survived until today, but two are listed as wrecks (Ty45-301

was scrapped, probably in 2003, Ty45-345 followed in August 2006 and Ty45-418

in 2007). Some of them are plinthed at various

locations. Two above-mentioned engines kept in working order have seen no

service for a couple of years due to boiler certificate expiry. Ty45-20 from Jaworzyna Śląska depot was

transferred to Wolsztyn in December 1999 and served

there until May 2000. Later it returned to Jaworzyna

and most probably will remain on static display. Wolsztyn-based

Ty45-379 (last example in PKP

service) hauled its last train in October 2002 and was then used for a couple

of weeks as a stationary boiler, to be finally withdrawn in February 2003. Main technical data

1)

Including 20 for industrial operators. 2) With

32D47 tender; 159 000 kg in working order with 30D43 tender. References

and acknowledgments

Concise

information can be found in PNP and

AP. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||