TKbb

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Fablok

4695/1956, photographed in Szczytno on Fablok 4719/1957,

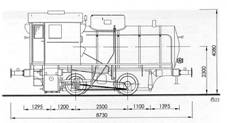

photographed on tha same occasion. Type 1U side drawing by M.Ćwikła (SK vol.8 /2003). Borsig

9690/1917, now exhibited at the Repty steam machines heritage park; photo

taken on Another

machine from Borsig:

TKb b4 (s/n 8464/1912) at the Wolsztyn depot. Photo taken on Hanomag 10282/1934 at the The

same locomotive, photographed on July 6, 2023. Derelict

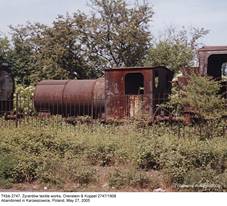

Orenstein

& Koppel

2747/1908 in Krzeszowice; photo taken on The

same engine, TKbb 2747, photographed in Chabówka on November 12, 2008. Formally owned by the

Railway Museum in Warsaw. In

June 2015 TKbb 2747 was transferred to Żyrardów, where it used to work years ago. Its current

condition, however, leaves much to be desired. July 6, 2024. |

TKbb designation applies, sometimes unofficially, not to a single class, but rather a group of miscellaneous fireless engines (hence second lower-case ‘b’, standing for ‘bezogniowy’ – fireless), which shared one common feature, namely 0-2-0 axle arrangement. Among them the indigenous type 1U, built between 1956 and 1967, was the most numerous one. Before WWII very few – if any – fireless locomotives were used in Poland. Indigenous design of a small, two-axle engine of this type, submitted by the Fablok works of Chrzanów in 1938, was not proceeded with. After 1945 rapidly expanding industry demanded new locomotives, including fireless ones (colloquially often referred to as ‘pasożyty’ – parasites), which were virtually irreplaceable in coking plants, steelworks, chemical plants and wherever high fire or explosion risk was involved. It should be kept in mind that first Polish diesel locomotives suitable for heavy industry appeared only in mid-1950s. Initially the need for fireless engines was satisfied by conversions of old freight machines, mainly TKi3s and Tp4s (Prussian classes T93 and G81, respectively), but in 1955 it was decided to develop a purpose-built locomotive of this type. This task was entrusted to the Fablok and the prototype (factory designation type 1U, s/n 4495) appeared in 1956, to be followed by 35 examples built until 1958 with serial numbers from 4692 through 4721 and 3881 through 3885. For some unknown reason, lowest numbers were allocated to last five machines, built in 1958. Welded boilers, or more precisely steam containers, were supplied by the Sosnowiec boiler plant. 1U was a small and straightforward machine, but compared to older conversions it had boiler pressure increased to 15 bar, which improved performance. Axle base of only 2.5 metres allowed negotiating tight curves (minimum radius 60 m), but with the 0-2-0 arrangement axle load of about 18 tons was comparatively high for an engine intended to operate on factory sidings. Steam cylinders were located below the driver’s cab. Prototype had steam collector, sand dome and safety valves covered by a long, streamlined fairing, which was deleted in production examples. Boiler feeding from a stationary plant took about 30 minutes or slightly more and this allowed for two to four hours at work, depending on season, operations performed and steam container insulation condition. Originally these locomotives had no lighting: kerosene or battery-fed headlights were installed individually by some operators. Later some examples were fitted with turbo-generators and electric headlights. As with other locomotives used by industrial operators, there was no uniform system of service designations. Some operators had their indigenous systems. Many engines were identified by TKbb plus serial, thus in part conforming to the PKP designation code. In late 1950s Fablok was ordered to concentrate all resources on the manufacture of diesel locomotives, so further production of the 1U was transferred to the ZNTK (Railway Stock Repair Establishment) of Wrocław, where several conversion had been made earlier. Only seven machines were assembled there (together with their welded steam containers) between 1961 and 1967. It is worth mentioning here that the last machine from Wrocław (s/n 7/1967, boiler serial 211) was in fact the very last steam locomotive built in Poland. This historical machine was sold to a coking plant in Zabrze, to be withdrawn after only three years’ service in 1970; unfortunately, nobody thought of preserving it... Fireless locomotives – simple in operation, undemanding and reliable – remained in service for a long time, even almost until the end of the 20th century. Three 1Us have survived until today. Two (Fablok 4695/1956 and Fablok 4719/1957), previously used by a textile factory in Szczytno, have somehow escaped the cutter’s torch, although their original owners went bankrupt in the 1990s; beautifully restored, they were for a long time plinthed at the premises of the FS Favorit Furniture company. Their service designations, if there were any, are unknown. In December 2014 they were transferred to Warsaw, supposedly as a part of newly-organized Museum of Transport collection (which, however, failed to open). The former was plinthed in 2017 near Czachówek Wschodni station at the premises of a private company. These were later abandoned and the engine dismantled and reduced to scrap. The latter was transferred to Gliwice in January 2016 and is currently plinthed at the premises of Gliwicka Fabryka Wagonów (Gliwice Wagon Factory). According to lists available at www.polskieparowozy.pl, two more Fablok-built 1Us still exist: 4698/1956 has survived in a poor condition at the premises of the former Wrocław gas plant, where it served until 2000 (!) as TKB/B 14813, and 4701/1956 is plinthed in Szczecin. As already mentioned, TKbb designation was in fact assigned to various fireless engines, including a number of old German locomotives taken over after WWII. Few details are available on their origin and subsequent service and their exact number is virtually impossible to estimate. According to a monographic article by Tomasz Roszak (SK vol. 7/2003 and vol. 8/2003), as early as in 1949 a brand-new 0-2-0 fireless engine was purchased from Henschel (s/n 27010/1949) for a coking plant. I have no information on its subsequent fate; further purchases from this manufacturer never followed, due to political rather than technical reasons. From this motley collection, four locomotives have survived until today. Borsig 8464/1912, once used by the Szczecin steelworks, can be seen at the Wolsztyn depot (designated TKb b4). Borsig 9690/1917, formerly operated by a power plant in Wrocław, is now exhibited at the Repty steam machines heritage park near Tarnowskie Góry. Two more, Orenstein & Koppel 2747/1908 and Hanomag 10282/1934, were operated by a textile plant in Żyrardów. The former was abandoned in Krzeszowice; in 2008 it was transferred to Chabówka and intended for refurbishment, but finally in June 2015 was transferred to Żyrardów and plinthed there. Its current condition is, however, rather poor. The latter can be seen at the Railway Museum in Warsaw. Main technical data

1) Some sources give 35, which refers to Fablok output only (excluding

prototype).

2)

Some sources give 8 740 mm – data possibly vary depending

on manufacturer 3)

Some sources give 6 400 kG 4)

SK gives masses at 25 000 / 35

000 kg, axle load about 18 T. References and

acknowledgments -

Monographic article by

Tomasz Roszak (SK vol. 7/2003 and vol. 8/2003); -

www.polskieparowozy.pl

(website by Tomisław Czarnecki). |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||