TKp (T2D, ‘Śląsk’)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Factory photo of the export TKp

version for TKp-2011, originally built for Klimontów

colliery, in Chabówka locomotive heritage park,

June 18, 2001. Another picture of the TKp

2011: May 6, 2017. TKp-20, Fablok 6289/1063,

Zduńska Wola Karsznice loco depot, June 20, 2001. Another picture of this engine, taken on August 13,

2008. OS (TKp-102), Fablok 982/1942, Skierniewice loco

depot, May 15, 2002. The same machine, photographed on September 17,

2006. Derelict TKp-5878, Gosławice sugar plant, March 6, 2001

(later scrapped) TKp

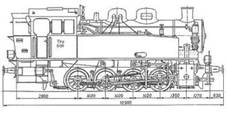

drawing from www.parowozy.best.net.pl

Two Duncan Cotterill's

photos from his website www.railography.co.uk

(thanks for permission!): Chinese ET7 5331 at Baotou

Steelworks in January 1990… … and ET7 5335 converted into tender engine (tender

from class PL2 locomotive). This TKp 2261 (Fablok

2261/1951) is designated TKp1, but has nothing to do with PKP class TKp1 (= Prussian T13); photo

was taken in Krzeszowice on May 27, 2005 by my

friend Waldek Rosiński.

This engine was later transferred to Pyskowice and

can now be seen there. Three of five (then) examples preserved at Pyskowice heritage park: TKp

4409… … TKp 6046 (both

from Dębieńsko

colliery… … and TKp 4422 from

Chybie

sugar plant – alive and well! All

pictures taken on October 9, 2004. More pictures of the TKp

4422, taken in Gliwice in June 2008, can be seen here. Another visit to Pyskowice

on May 2, 2009: TKp 6046… …and TKp 4409, both

photographed for the second time… …Tkp 2261,

transferred from Krzeszowice… …TKp 3409, awaiting

refurbishment… …TKp 15132… … and TKp 15347

(OS), unfortunately in a rather poor condition. This TKp-2816 (Fablok 2816/1951, withdrawn in

1993), photographed at PCC Rail Polska premises in Szczakowa

on March 3, 2005, was moved to a new location in Wieliczka

on June 22, 2010, and plinthed with an incorrect

designation TKp-2316. TKp 5485 (Fablok

5485/1959), NVR, photographed

during the 2005 Steam Gala at Wansford, UK on July

23, 2005; more photos taken on this occasion can be found here. TKp 6042 (Fablok

6042/1962) under restoration at the Skierniewice

depot; photo taken on August 6, 2005. Another picture of TKp

6042, taken on September 17, 2006; restoration almost completed. This photo of the TKp

16 (from my collection) was probably taken somewhere in mid-1990s, prior to

the sale of this engine to VVT. TKp 5351 (Fablok 5351/1960), still in

service. Photo by J.Weselik (postcard from my

collection). This engine was withdrawn around 1990. Another picture of the TKp

5351, possibly taken on the same occasion. Fablok 2239/1950, built for the Łabędy steelworks

(service designation HŁ-16), plinthed at the Kraków Płaszów station; photo

taken on September 9, 2006. Another picture of this engine, taken on

November 25, 2009. TKp 26188 (Henschel 26188/1944),

displayed at the Białowieża Towarowa

station, is a private property. Motion gear is missing. Photo taken on July

16, 2011. TKp 2261, photographed in Krzeszowice prior to

transfer to Pyskowice (date unknown). Photo from my

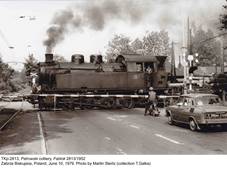

collection. Once a common view in Upper Silesia:

TKp-2813, operated by Pstrowski

colliery, photographed in Zabrze Biskupice on June

10, 1979. Photo by Martin Stertz (from my collection). TKp, number, location and date unknown. Surroundings suggest that this

may be another picture of the TKp 5351 (see above),

but confirmation is lacking. Photo from my collection. TKp 5 (Fablok

6041/1962), originally delivered to Siarkopol Tarnobrzeg sulfur mine, has finally found its way to

the Industry and Railway Museum in Jaworzyna Śląska; May 25, 2016. |

Shortly after WWII there was a demand for virtually all kinds of locomotives and rolling stock. Among others, a simple and reliable tank freight engine was necessary for rapidly expanding heavy industry – collieries, steel plants and other similar establishments. Typical line locomotives were not well suited for such service on factory sidings: they were too large, uneconomical and difficult to maintain. It was thus decided to build a suitable switcher, modern and undemanding, and the choice fell on a German design, developed by Henschel and built by several manufacturers for industrial operators (this type never served with state railways). This locomotive was also built during the war at the Fablok factory in Chrzanów (then Oberschlesische Lokomotivwerke Krenau A.G. – 25 examples, built in 1942). Fablok-built engines were intended for service mainly on factory sidings in the Upper Silesia and hence named ‘Oberschlesien’ or just OS. With the 0-4-0 axle arrangement, it was well suited for industrial service and had sufficient tractive effort. At least six locomotives of this type (possibly more) were used in Poland after the war. Polish prototype, also built at Chrzanów (factory designation T2D – sometimes written as T-2-D), which appeared in 1950, did not differ much from its German predecessor. OS had been built in variants running both on saturated and superheated steam and the latter was chosen as a prototype. For the sake of simplicity and ease of manufacture, riveting was widely supplanted by welding, and boiler accessories of normalized Polish types (also used by PKP) were fitted. Series production started soon afterwards and continued until 406 examples had been built. 316 of them were supplied to various industrial establishments in Poland, mostly in the Upper Silesia. These engines, commonly named ‘Śląsk’ (Silesia), were quite conventional and straightforward machines, designed for effectiveness and hard everyday work rather than brilliant performance. They gave useful, if inconspicuous service and remained in use for a long time. Several examples were still in working order in mid-90s, when virtually all line steam locomotives had already been withdrawn from regular service. Stock list of the Wieczorek colliery in Katowice in 1992 still included TKp 5512, used for switching. TKp-3394, from another Silesian colliery, was probably operational in mid-1990s and scrapped after 1998. Modernizations introduced during their long life were few and included modified lighting and draw-gears. Ninety T2Ds were sold to China between 1961 and 1962 (some sources give 102). They were designated class ET7 and slightly modified, according to Chinese standards: driver’s post was repositioned to the left, boiler accessories were changed and knuckle couplers were fitted. Driver’s cab was of the closed type. Several examples were converted into tender locos with their water boxes removed. Some of these machines remained in service until mid-1990s and three were reported in good condition in April 2004. Many interesting details and current photos can be found at Duncan Cotterill’s website www.railography.co.uk/tractive-efforts. In 1959 a contract was negotiated between Fablok and Albanian railways, but with no result, as Albanians needed mainly line locomotives (and finally bought six TKt48s). Production of this type was terminated in 1963 and they were the last steam locomotives built by Fablok – in fact the engine with serial number 6293 was the very last one. No locomotive of this type was used by PKP; therefore – in accordance with typical practice – their designation just reflected the axle arrangement, without any class number. Individual operators allocated service numbers without any common sequence (often corresponding to serial numbers, but this was never the rule). Some operators had their own designation systems, with no relevance to axle arrangement or any other feature. For example, Łabędy steel plant in Gliwice designated their locomotives by letters HL, followed by a number. As it has often been the case with steam locomotives owned by industrial operators, many of them after withdrawal from service were just left to rust on some forgotten sidings. In March 2001 I saw one of them, namely TKp 5878, by Gosławice sugar plant; it was scrapped a few months later. According to data from www.kolej.pl/tabor/parowozy (unfortunately, this link has been dead for some time), TKp 2066 had also been kept in Zebrzydowice, but recent sources don’t confirm its existence. Very comprehensive lists of preserved steam locos, available at www.holdys.pl/tomi/ (site maintained by Tomisław Czarnecki) and updated in November 2010, give sixteen examples at various locations in Poland; two more (TKp 3407 and TKp 5905), kept in Krzeszowice, were scrapped in 2006. Eleven are preserved in various heritage parks and two are plinthed (in Kraków and Gliwice). Three are listed as ‘wrecks’, so their future may be rather uncertain. Railway stock heritage park at Pyskowice, owned by the TOZKiOS society, has six engines of this type, but one of them (TKp 5161, Fablok 5161/1958) is kept dismantled. This collection includes TKp 4422 (s/n 4422/1955) transferred from Chybie sugar plant, which was kept operational for a few years. Currently (late 2010), after boiler certificate expiry, this machine is awaiting a decision on its future – I hope it will be restored in service. Original German locomotives, built before 1945, have also been given the TKp designations. Three of them have survived until today. TKp 15347 (Borsig 15347/1942) from the Rokitnica colliery can be seen in Pyskowice and is awaiting restoration. TKp 26188 (Henschel 26188/1944) served at the Sośnica colliery until 1975 and was initially intended for preservation at the railway museum in Warsaw. After several years of abandonment in Krzeszowice it was purchased by a railway fan and is currently on display at the Białowieża Towarowa station. TKp 102 (Fablok 982/1941, but built in 1942) has been preserved by PSMK railway fans society at the Skierniewice locomotive depot. This machine had enjoyed a long service life with sand railways and the Kazimierz Juliusz colliery and was finally withdrawn in April 1995. PSMK has yet another ‘Śląsk’: – TKp 6042 (Fablok 6042/1962), transferred from a Silesian colliery, currently under restoration. According to the above-quoted Internet source, as many as nine machines of Fablok post-war production were sold abroad between 1989 and 1996 to various heritage railways and railway societies, namely: - VVT (Vapeur Val-de-Travers), Switzerland (2667/1952, designated TKp 16; this engine has recently been withdrawn and awaits boiler overhaul – many thanks to Urs Hudritsch for information!), - Veluwsche Stoomtrein Maatschappij, Beekbergen, The Netherlands (4429/1953 – operational, designated TKp 23, and 5353/1957 – static display), - Nassauische Touristikbahn, Wiesbaden, Germany (4408/1955 – static display), - Stoomcentrum Maldegem, Belgium (4430/1955 – resold in 2005 to CITEV, France, now undergoing overhaul at MALOWA, Klostermansfeld, Germany; 4436/1955 – stored; and 6281/1963 – operational, last major overhaul in 2002; many thanks to Rik Degruyter and Jason Van Landschoot for information!), - Nene Valley Railway, Wansford, UK (5485/1959 – operational), - Stoomtrein Hoorn, The Netherlands (5150/1958 – current status unknown). Preserved Locomotives of British Railways by Peter Fox and Peter Hall

(Platform 5, 2002) lists also 3399/? – probably 1954 – owned by Pontypool & Blaenavon

Railway; this, however, is not confirmed by their website. According to

some sources, TKp-101 (Fablok 2013/1950) has also been offered for

sale. No details are available; according to the above-mentioned list of

preserved locomotives, this machine is still (late 2010) kept in Przezchlebie in Upper Silesia in a very poor condition. Main technical data

1)

According to less reliable sources. Ninety examples,

slightly modified, sold to China. This number does not include at least six

OS machines, impressed into the TKp class. Some

sources give that export to China amounted to 102 machines. 2)

Other sources give Knorr brake. List of surviving examples is available here. References and

acknowledgments -

www.parowozy.best.net

(website by Michał ‘Doctor’ Pawełczyk); -

AP, PNP; -

www.kolej.pl/tabor/parowozy (this

link is no longer active); -

Rik Degruyter, Jason Van Landschoot and Urs Hudritsch (private communications); -

www.holdys.pl/tomi (website

by Tomisław Czarnecki); -

www.railography.co.uk/tractive-efforts

(website by Duncan Cotterill - many thanks for the

photos!). |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||